A

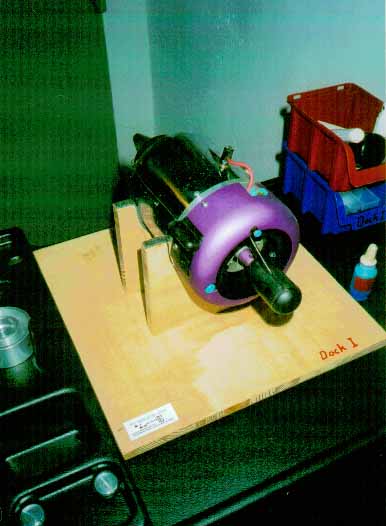

routine service consists of taking the turbine apart and cleaning, which

partly takes place in an ultrasonic bath. Afterwards each module becomes

tested as to possible damages and abraison. If the assessed damage is

serious, the customer will be directly contacted for further arrangements.

If not, the bearing will be replaced and the rotor disk balanced. To this

the turbine gets assembled and a test run is carried out.

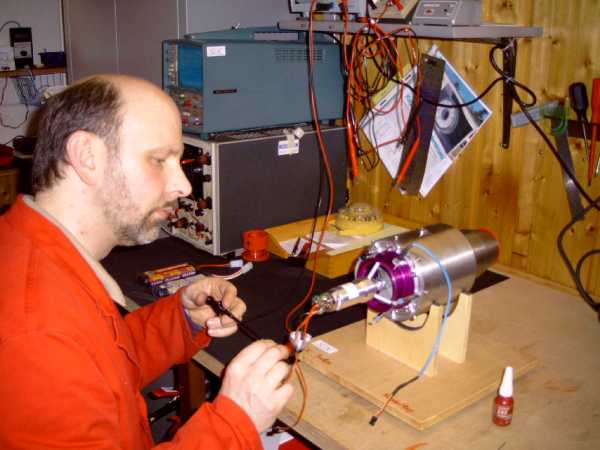

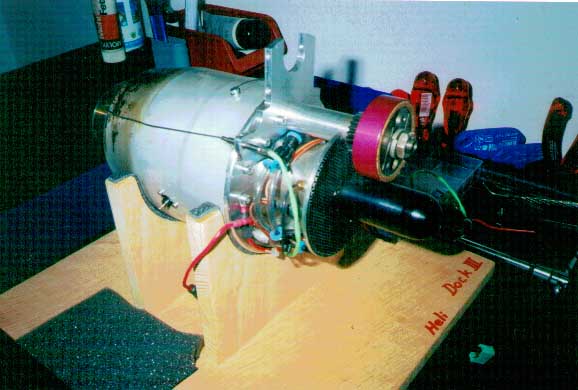

Turbine

test runs follow after repair ending. Common electronics are assembled,

but

nevertheless it is advisable to attach by sending the own

electronics including pump (especially for

Jakadofsky, JetCat-RX i, NX,

JetCentral, Jets Munt, Lambert Kolibri, King Tech, and

Simjet-ECU’s). The

consignment will either leave by Deutsche Post,

and DHL-service incl. 500 EUR insurance.

Current

running time in-house for a standard turbine maintenance takes approx. 3 - 4

weeks after receipt.

„Just in time processing“

In

any case possible changes will be discussed with customer beforehand.

|

|

|